By now, it’s difficult to ignore the news about polytetrafluoroethylene (PTFE) and the health concerns surrounding the potential by-products that can be generated when producing it. The challenge has been in finding chemistries that provide equivalent performance while overcoming its drawbacks and regulatory hurdles.

PTFE has been used for many years in a wide range of applications for its exceptional chemical and temperature resistance, low coefficient of friction, and enhanced surface durability. In the coating and ink industry, low-molecular weight PTFE greatly improves surface protection of coated or printed materials from abrasive forces during processing, transportation or use. PTFE used in combination with other waxy polymers maximizes protection properties for specific formulations, substrates, film thickness and performance requirements.

Producing low-molecular weight PTFE, like the type used in coatings, requires an irradiation process that generates PFAS components [e.g. perfluoro octanoic acid (PFOA)and perfluoro-octane sulfonic acid (PFOS)], which are health concerns. Those concerns include being persistent in the environment, bio-accumulative in humans and animals, toxic, and suspected of being carcinogens.

Government regulators have either addressed these concerns or are considering addressing them. Regulations from the EU in 2019 restrict the use of raw materials containing >25 ppb PFOA, which impacts the use of PTFE because of common production processes that use irradiation.

There have been two paths forward in exploring compliant solutions without sacrificing performance: formulate with low-PFOA PTFE or develop new technologies that eliminate PTFE.

PTFE-free materials have typically been the preferred path and where more focus has been placed as compared to the low-PFOA path. PTFE-free materials generally have three options to reach that status:

- Remove PTFE from the wax additive

- Remove PTFE and add inorganic functional components

- Remove PTFE and add organic functional components

Wax additives have become an increasingly popular way to replace traditional PTFE with PTFE-free alternatives. Lubrizol has concentrated on continuing to expand our PTFE-free alternative wax additives to provide similar properties to PTFE-containing additives. These additives use new and alternative raw materials that function in a similar way to PTFE.

Lanco™ Surface Modifiers

Lubrizol PTFE-free technologies are available in micronized and dispersed forms of surface modifying additives under the Lanco™ Surface Modifiers brand that deliver similar properties to PTFE-containing additives. Through extensive testing and now commercial availability, the technologies are on hand to enable ink and coating formulators to successfully make the transition to avoid current and future regulatory pressure. These PTFE-free additives are used in a variety of applications, including can and coil coatings, general industrial (GI) coatings, wood coatings and printing inks.

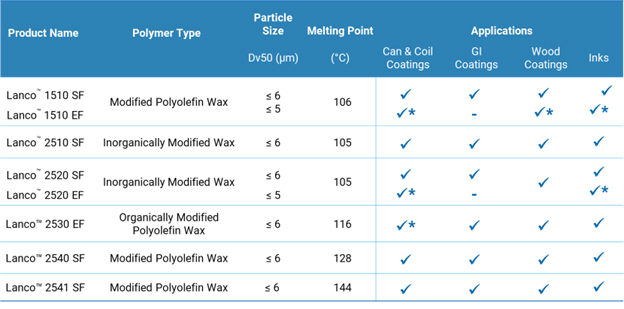

Lanco™ PTFE-Free Micronized Waxes

* thin film

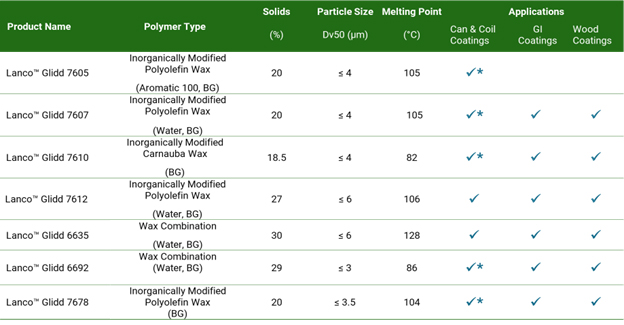

Lanco™ PTFE-Free Wax Dispersions

* thin film

Delivering Similar Properties

Lanco™ PTFE-Free Wax Additives offer a number of comparable benefits when used as a replacement for waxes containing PTFE in specific applications, such as good scratch and abrasion resistance for surface protection, good rub resistance, uniform matting, good clarity to maintain visual effects, and improved slip and surface smoothness. Formulators also have control over gloss to achieve the desired appearance.

Lubrizol continues to develop and test more products to meet specific customer needs and to provide additives for a wider range of applications. Existing products can also be customized as needed to avoid PTFE.

Contact us to learn more about our PTFE-free wax additives.