- myLubrizol

-

-

Search Pharmaceuticals

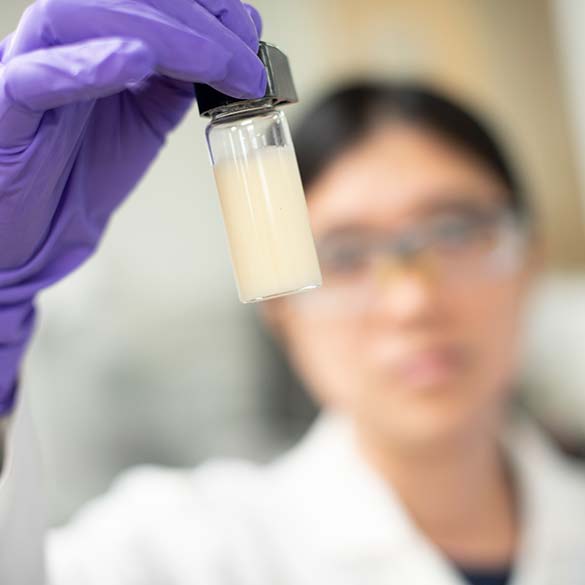

With many generic carbomers containing hazardous residuals and not meeting both safety and quality demands, Lubrizol’s Carbopol® polymers offer a significant advantage. As the global carbomer of choice, Carbopol® polymers help formulators maintain consistent quality, safety, sustainability, and global supply chain security throughout the product lifecycle.

Excipient functions range from assuring the stability and bioavailability of the active ingredient (API) to a drug products appearance, texture, taste, and manufacturability.

A pharmaceutical formulator should be aware of the complexities of the excipient world and must choose the excipient type, grade, and its manufacturer judiciously. Invented in 1958, Lubrizol’s Carbopol® polymers continue to be the carbomer of choice for global pharmaceutical formulators.

Unlike many generic carbomers, Carbopol® polymers are synthesised to meet the highest safety standards. Generic carbomers may be synthesized in Class I or Class II solvents and may not provide full disclosure of the residuals and their testing methods. However, Carbopol® polymers are manufactured using toxicologically preferred solvent systems and provide full disclosure of the residuals along with validated testing methods in order to ensure the highest level of safety and purity. With compendial and regulatory compliance and quality, product and patient safety is key for LLS Health.

With a wide range of manufacturing benefits, Carbopol® polymers are well-known for their versatility as pharmaceutical excipients. Lubrizol continues to invest in innovation from their strategically located and well-equipped technical service and application centers around the world. Lubrizol scientists have done extensive work on applications of Carbopol® polymers to provide unique benefits to the global formulators in all dosage forms.

As one pharma formulator discovered when reformulating its widely used oral suspension product, it is not always clear which low-cost carbomers are safe to use, and which are not. In fact, these lower quality carbomers can prove costly in the medium term, especially when considering the potential risks associated with regulatory non-compliance.

In an industry where the global regulatory environment is fragmented, formulators and manufacturers need to know the standard of their excipients.

Is your carbomer safe? Find out what to look out for.

For drug formulators to ensure they select carbomers that are of the highest safety standards, it is important for them to have a deeper understanding of local and global regulatory requirements. Find out more about regulatory landscape and how Carbopol® polymers are compliant with the regulatory requirements