Applications

Cardiovascular, Electrophysiology, Neurovascular, Diagnostic, Endoscopy, Gastrointestinal, Nephrology, Neuromodulation/ Neurostimulation, Urology, Coronary

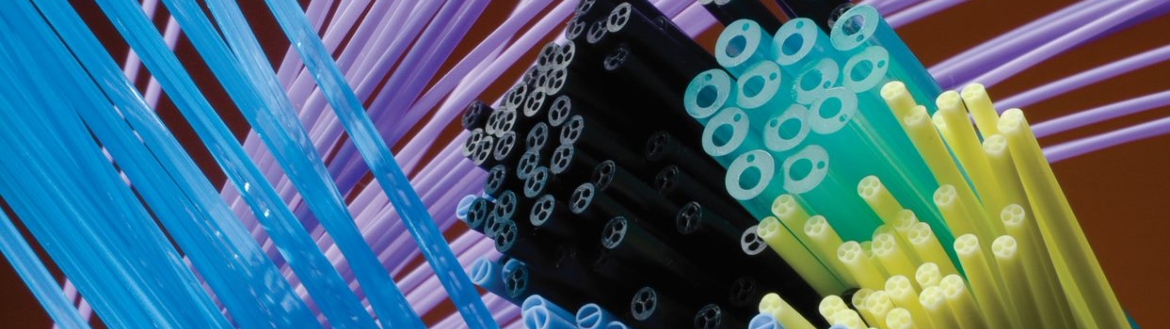

Lubrizol Life Science Health’s precision medical extrusion solutions optimize the clinical outcome of medical devices with precision braided tubing manufacturing services for the medical device industry.

Function

Braiding enhances the functionality of a catheter by improving its mechanical properties, enabling devices the ability to navigate the tortuous anatomy and address a variety of medical procedures. Braided shafts exhibit the following characteristics:

- Flexible with high kink resistance

- Increased column and burst strength

- Collapse resistance features

- Excellent push-ability and torque transmission properties

Description

Braided tubing is a common solution for increasing the tube’s burst strength while producing thinner walls and smaller profiles in the extrusion process.

Using radiopaque material, braided tubing can be viewed under X-ray. LLS Health’s experienced engineers provide medical device design assistance to help optimize your braided shaft and overall product performance.

Technology

Integrating Materials, Tooling, Process and Quality Control

Our experienced NPD team uses dedicated equipment and innovative technology to tailor performance to your requirements and develop an efficient and consistent manufacturing process.

Competency

- OD sizes from 0.030"–0.200" (0.762mm–5.08mm)

- Round or flat wires available

- Materials: stainless steel, nitinol, fibers and filaments

- Capabilities include 16 and 32 carrier braiders

- Stainless steel wire ranging from 0.001"–0.010" (0.0254mm–0.254mm)

- Braid angles from 20°–70°

- Cut lengths or spool

- 25–125 picks per inch rates

- Variable or constant pick pattern

- Continuous layer processing

- 15%–95% coverage