Proven Device Design Guidance and Support, from Concept to Commercialization

At Lubrizol Life Science Health (LLS Health), our innovative medical device design group consists of a highly experienced and fast-working team that’s ready to support you throughout the device design process, including feasibility, design reviews, design freeze, design verification, design validation, and, finally, an approved and ready-for-market product.

LLS Health can also efficiently manage your project, provide scheduled team calls and interactions to provide updates and achievements to set milestones, and help you shorten timelines and expenses. Whether starting with an existing design requiring new features and optimization, or starting from a sketch on a napkin, we can help you realize your next innovative solution.

Your Partners for Achieving World-Class Medical Devices

At LLS Health, we pride ourselves in our ability to offer a broad range of unique services and capabilities from across the globe. These include:

- Good manufacturing practice (GMP) environment for drug coating.

- Design centers and full device manufacturing facilities across two continents and three countries: United States, Germany and Romania.

- New Device Design and Manufacturing group located in Southern California.

- Platform designs for percutaneous transluminal angioplasty (PTA), percutaneous transluminal coronary angioplasty (PTCA), neurovascular and ear, nose and throat (ENT).

- Nearly 30-year history of success, with first device development dating back to 1992.

- Relationships with well-known institutions and key opinion leaders.

- Material expertise and polymer chemistry from Lubrizol Medical Polymers.

- Support for combination devices with drug development capabilities with Lubrizol CDMO.

Design Services for the Most In-Demand Therapies and Expertise

For a constantly evolving medical industry, the LLS Health device design team is experienced in covering a broad range of therapies and clinical expertise, including:

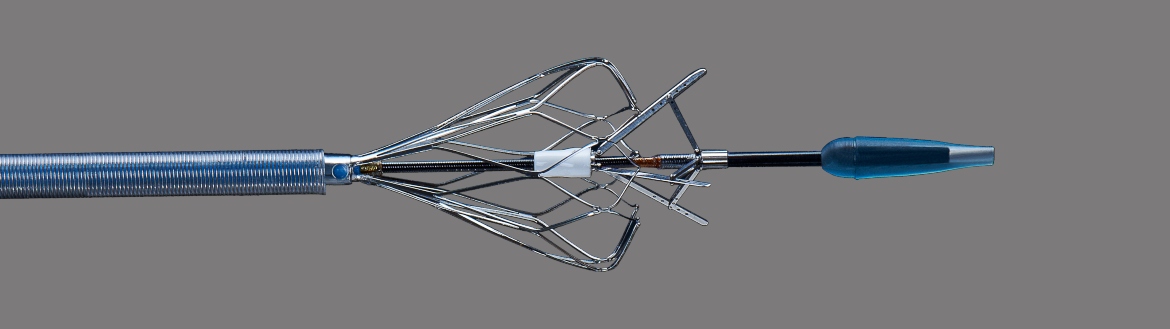

- Interventional Cardiology: Angioplasty catheters, aspiration, perfusion, stent delivery and local drug delivery

- Interventional Radiology/ Peripheral Vascular: Angioplasty catheters for above and below the knee applications and local drug delivery

- Cryotherapy: Incorporated sensors and thermocouples in dilatation catheters

- Neurovascular and Neuroradiology: Angioplasty catheters, stent delivery and local drug delivery

- Structural Heart: Delivery devices/access devices for TAVI/TAVR and transseptal puncture

- Ear, Nose and Throat Therapies: Dilatation catheters and local drug delivery

Our Trusted Processes for Designing Your Next-Generation Device

After choosing to partner with LLS Health for your next device, we can help ensure device excellence through each step of our trusted processes, which include:

- Product Design: If you have an idea about a clinical need, a specific indication or a special device, we can help you decide on the best design. Our design engineers work closely together with you and your medical advisors to satisfy your individual needs.

- Device Customization: If existing devices are a good baseline but do not completely fulfill your needs and requirements, we are able to customize them according to your individual specifications.

- Balloon Design and Forming: We have various in-house balloon forming technologies and can provide a huge range of different balloon sizes, balloon characteristics and balloon materials.

- Stent Crimping: We can crimp your stents, coated or uncoated, onto our balloons. We have different in-house crimping technologies, and the crimping process will be validated for your specific stent in order that you can rely on constant product performance.

- Drug Coating of Balloons: Many of our dilatation catheters are used for “combination devices”, i.e., a combination of an active drug and a medical device.

- Packaging, Labeling, Sterilization: If our customers do not want to engage in the production process at all, we also offer ready-to-go products including packaging, labeling, external sterilization and shipment.

- Product Transfers: If your strategy is to optimize and reduce cost, or outsource a particular product or product line, our device design and device manufacturing teams can facilitate your efforts with options for lower cost manufacturing environments.

- Regulatory Support and Product Approvals: We offer all the necessary support with regional regulatory agencies required to gain product approval in most parts of the world. Learn more about our regulatory support capabilities and view helpful regulatory resources here.