Helping Partners Achieve Improved Functionality and Performance through Seamless Device Manufacturing Processes

If you’re looking for white glove service when it comes to manufacturing your next medical device, Lubrizol Life Science Health (LLS Health) has all the materials and manufacturing expertise to meet your expectations.

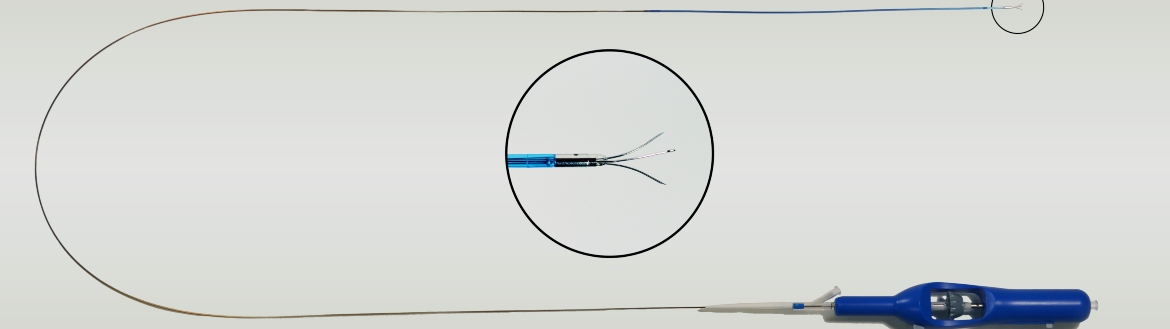

In addition to component and sub-assembly manufacturing at three sites in the United States, your finished device manufacturing needs are provided for by our manufacturing sites in California, Germany and Romania. We manufacture a variety of different medical devices, including catheters for coronary, peripheral, neurovascular, structural heart and cranial indications, dilatation catheters, devices for local drug delivery, stent delivery devices and ear, nose and throat (ENT) devices.

As a pioneer in drug-coated balloons, we also offer the drug coating with your specific coating formulation. The drug coating takes place in our dedicated good manufacturing practice (GMP) clean rooms.

Products are manufactured according to our customers’ specifications, but there are also devices available with CE approvals. Devices can be delivered packed, labeled, sterile or non-sterile, depending on the customers’ needs.

Manufacturing Processes that Deliver Value Beyond the Device

At LLS Health, we understand the importance quality manufacturing has on your lead times, regulatory compliance and bottom line. That’s why we offer all the necessary manufacturing processes to help get your device to market as quickly and efficiently as possible.