Applications

Coronary, Peripheral, Neurovascular, Dilatation, Drug and Device Delivery, Occlusion, Nonvascular and More

Lubrizol Life Science Health’s precision medical extrusion solutions optimize the clinical outcome of thermoplastic balloons for the medical device industry.

Quality

LLS Health’s balloon tubing produces:

- High-yielding medical device balloons

- Uniform wall thickness with excellent concentricity

- Visually clear and tight cosmetic specifications

- Repeatable mechanical properties necessary for critical clinical applications.

We provide medical device design assistance to ensure optimal clinical outcome. LLS Health’s fully integrated facility utilizes stringent manufacturing controls necessary to ensure optimal balloon performance.

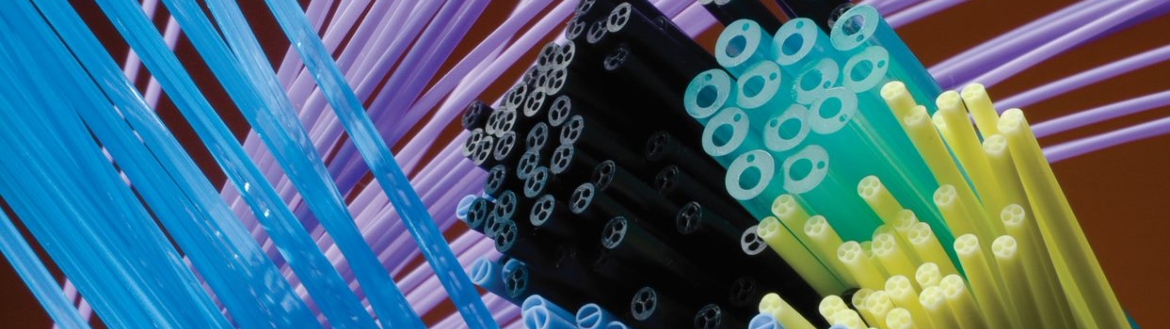

High-Quality Balloon Tubing, Thin Walls and High Burst Pressures

LLS Health’s experienced team ensures that the tubing meets customer-specified dimensional and mechanical requirements. Our expertise includes:

- Balloon tubing manufacturing

- Excellent concentricity > 90%

- Wall thickness tolerance ± 0.0005" (± 0.012 mm)

- Tight dimensional tolerance ± 0.0005" (± 0.012 mm)

- Repeatable mechanical properties, such as elongation and tensile strength

- Inspection of tubing for cosmetic defects

- Multi-layer constructions

- Testing: fatigue, burst, collapse, moisture content, tensile, elongation

- Materials: Nylon, Polyamides, TPU, Polyolefin

- Custom materials available by request

- Irradiation for balloon tubing

- Rapid extrusion services

- Proprietary process and inspection methodology to control and minimize gels