Lead Extrusion Solutions Backed by Meticulous Precision and Uncompromising Quality

By partnering with Lubrizol Life Science (LLS) Health, we can provide high-quality lead extrusion while also formulating the proper polymers. LLS Health offers industry-leading TPUs like Carbothane™, Tecothane™ and Pellethane® that provide thinner walls, more flexible lead design and unmatched overall quality resulting in far less issues than other materials during the manufacturing process.

Extreme Precision for Critical Medical Applications

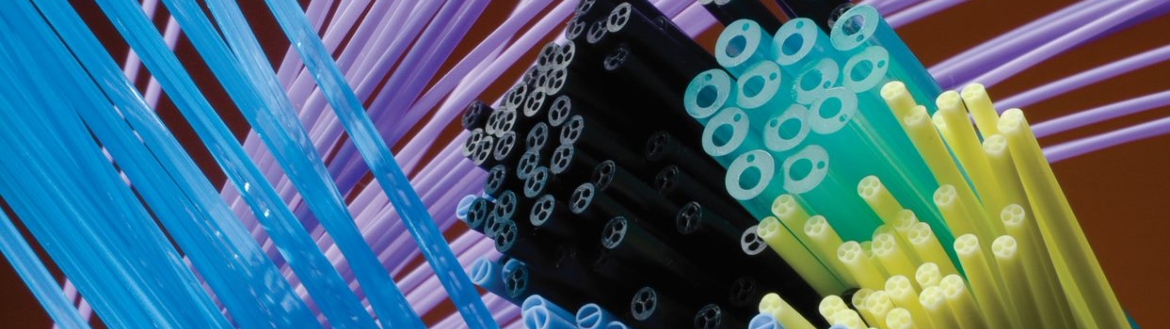

LLS Health offers a broad range of TPUs and silicone materials for delivering lead tubing and extrusion solutions for the most sensitive and complex medical applications, including cardiac rhythm management and neurostimulation and insulation and implantable lead extrusion for active electrode applications.

Materials, Tooling, Processes and Quality Control to Meet Every Need

LLS Health lead extrusions adhere to the highest level of precision for dimensional, surface, cosmetic and mechanical properties. In addition, our comprehensive processes and quality control ensure correct tolerance, surface finish and cosmetic specifications for all our lead tubing. We optimize product attributes by developing material-specific extrusion processes, customized tooling and product specific inspection procedures. Our proven annealing process relieves the internal stresses and dimensional instability inherent in polyurethane tubing.

Coupled with the quality of our TPUs, such Pellethane®, LLS Health’s quality assurance team is well trained and experienced in inspection of lead to ensure it meets the critical and stringent quality requirements for lead extrusion and that there are no issues during inspection, assembly or any other step during the manufacturing process.

Industry Competence that Provides Confidence

LLS Health’s technicians and engineers have decades of combined experience in lead extrusion and understand its critical nature. We are a valued supplier to most of the leading CRM and neurostimulation OEMs in the market today. Our expertise includes:

- Materials:

- Polyester and polyether urethane (TPU)

- Aromatic and aliphatic urethane (TPU)

- Polycarbonate-urethane co-polymer

- Tight wall tolerances of ± 0.0005" (0.013 mm)

- Annealing for stress-relief

- Single-lumen and multi-lumen configurations

- 100% visual inspections, as required