- myLubrizol

-

-

Search Engineered Polymers

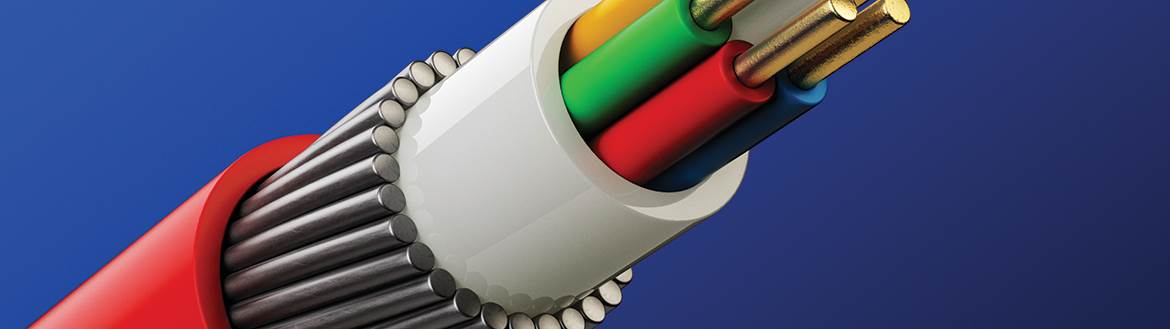

Our ESTANE® TPU portfolio for electric vehicle charging cables provide durability, recyclability**, high flexibility and abrasion resistance.

ESTANE® TPU can be easily extruded into wire and cables. View On-Demand Webinar and learn how:

Watch+1 216-447-5000