Meeting the design and reliability demand requirements of flexible electronics requires not only unique, individual high-performance materials, but a deep understanding of how materials interact to create functioning flexible devices.

Our broad understanding of materials science and global supply chain partner network ensures integrated film, adhesives, foams, coatings and fabrics perform beautifully together.

Through collaboration, our tailored solutions for flexible electronics promise proper integration, continuous product advancement and speed to market.

Automotive |

Health Care |

Consumer Electronics |

Industrial |

|

|

|

|

Traditional rigid electronics can no longer accommodate emerging technologies due to stiffness constraints, heavier weight and lack of conforming requirements.

Key drivers can be highlighted as:

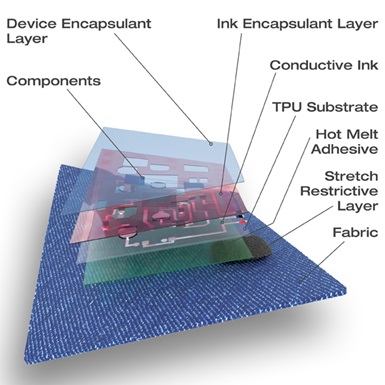

In collaboration with our global supply chain partners, we developed a Multi-Tech Commuter Jacket (MTC) that includes stretchable, flexible printed circuits with high performance ESTANE® FS TPU films and conductive ink coatings. The project highlights the importance of systems thinking in the development of novel wearable electronics, combining design, materials science, applications know-how, and value chain partners having the right mindset and capabilities, to quickly turn innovative ideas into prototypes and then commercial scale realities.

Lubrizol will no longer provide the films; however, the resins for the specific films will be available for purchase. The resins, then can be extruded through chosen extruder to target specifications.

ESTANE® FS TPU Flexible TPU Film

This table provides a reference chart for corresponding resin for each film.

|

Film |

Resin |

Max. Tensile* Elongation (%) |

Tensile* Set @200% Elongation |

Benefits |

|

|

ESTANE® FS H92C4P |

FS H92C1 |

350 |

15 |

High in adhesion; Very good hysteresis; 150oC ink cure temp. |

|

|

ESTANE® FS L85B4P |

FS L85B1 |

600 |

10 |

Very high in adhesion; Very good hysteresis; 115oC ink cure temp.

|

|

|

ESTANE® FSL75A4P |

FSL75A1 |

700 |

4 |

Very high in adhesion; Very low tensile set; low stretching force 115oC ink cure temp. |

|

*Tensile measurement at 100um film thickness.