- myLubrizol

-

-

Search Immersion Cooling

As data centers around the world grow in both computing power and scale, the need for more effective cooling solutions has emerged as a significant operational challenge.

The good news? Immersion cooling, where server electronics are fully submerged in a dielectric liquid cooling system, has proved itself to be an ideal solution for turning down the heat in data centers of any size or scale. Enthusiasm for liquid cooling is being driven by forward-thinking data center operators, especially cloud service providers, and revenue for the liquid cooling market may top $3 billion by 2026.

But not all immersion cooling setups are the same, and the right dielectric fluid formulations for your specific hardware are critical for success. Read on to learn why working with partners who can custom formulate fluids best suited to your needs can lead to even higher efficiency gains and effective cooling.

Single-Phase Immersion Cooling: Ideal for Customization

Single-Phase Immersion Cooling: Ideal for CustomizationFirst, it’s important to distinguish between single-phase and two-phase immersion cooling setups.

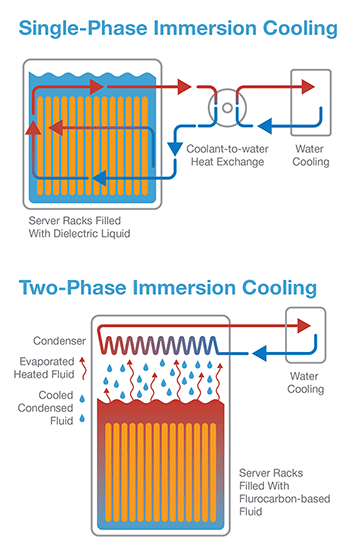

In single-phase immersion cooling, hardware is submerged in a dielectric fluid that makes direct contact with the IT equipment, conducting heat away as the fluid flows through a heat rejection mechanism, such as a heat exchanger, which is typically operated with facility water. Organic or halogenated fluids may both be used in this application, although the latter are typically associated with higher cost and maintain a less favorable environmental sustainability profile.

In two-phase cooling, a fluorocarbon-based fluid readily boils when in contact with equipment hot spots, transitioning the fluid from a liquid to a vapor that can be condensed in a heat exchanger and recirculated into the cooling tank. This phase change of liquid to gas allows the fluid to draw large amounts of heat from the equipment, but also requires integration of system design elements to facilitate the transition and a sealed system to prevent costly fluid loss from evaporation.

Both single-phase and two-phase systems offer superior efficiency, high-density performance, and cooling characteristics versus conventional systems. However, there is significant potential to tailor the fluid in a single-phase system, creating an opportunity for solutions that meet the needs of future hardware.

Early generation immersion cooling fluids were sourced straight from the refinery, designed for different applications and industries and repurposed for use in data centers. While this approach enabled early access to immersion-capable fluids, these options are not sufficient to maximize equipment lifetime and performance or to meet the more demanding thermal requirements of next-generation equipment.

But today, immersion fluids that have been designed and developed specifically for your unique needs can offer optimized performance properties and better material compatibility. For example, fluid durability is a critical characteristic for immersion cooling—the fluid’s useful life should be maximized in order to minimize the need for periodic change outs, leading to downtime and required maintenance. Additionally, as power demands increase, next-generation fluids should be able to help extend the useful life expectancy of their hardware.

While some available immersion cooling options are “one-size-fits-all,” there’s no need to settle when you work with the right supplier. Ideally, your immersion cooling partner should be able to tailor your fluid, offering balanced properties and better material compatibility to meet the unique needs of your data center facilities and equipment. And as power demands increase, properly engineered immersion cooling formulations can help extend the life expectancy of your hardware, leading to lower total cost of ownership over the long term.

CompuZol™ immersion cooling fluid solutions from Lubrizol can be the specific solutions hyperscale data centers need to overcome cooling challenges. Working closely with leading computing companies, Lubrizol and our team of fluid engineers can play a critical role in the continued evolution of immersion cooling technology, helping the hyperscale data centers hardware achieve scalable solutions necessary to meet their full potential. Contact your Lubrizol representative to find out how CompuZol can transform your operations today.